Super infrared Thermal Imaging 640×512 thermal camera analyzer for PCB and hardware

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for Super infrared Thermal Imaging 640×512 thermal camera analyzer for PCB and hardware, Our products and solutions delight in fantastic popularity among the our buyers. We welcome prospects, company associations and close friends from all areas of your world to get in touch with us and seek out cooperation for mutual gains.

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for thermal measurement temperature measurement thermal imaging test meters, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Overview

- CA Pro Series Integrated Thermal Analyzer is able to detect and measure the data of an object’s temperature changing with time based on the principle of infrared detection and imaging, and store and analyze the reliability of the measurement results without time limit.

- It is mainly applied in the location, detection and maintenance of PCBA leakage, short circuit and open circuit; the evaluation and comparison of mobile phones or other smart devices; auxiliary analysis of electronic equipment performance; temperature control of electronic atomizer; temperature conduction analysis of heat conducting and radiating materials; uniformity analysis of materials; heating experiment, thermal simulation and verification of heating rationality in circuit design; and thermal design data analysis, etc.

Application

Detection of short circuit and electric leakage of the PCBA

Analysis of the heat dissipation rationality of the PCBA

Evaluation of the thermal conductivity and heat dissipation of materials

Analysis of temperature control of the atomizer heating of electronic cigarettes

Analysis of thermal effect of components

Analysis of heating rate of heating materials

Other analytical applications: Analysis of LED guide plates, quality analysis of optical fiber welding, loading analysis of components…

♦ specification

| System parameters |

CA-20 |

CA-30 |

CA-60 |

| IR resolution |

260*200 |

384*288 |

640*480 |

| Spectral range |

8~14um |

||

| NETD |

70mK@25℃ |

50mK@25℃ |

|

| Angle of visual field |

36°X25° |

56°X42° |

56°X42° |

| Frame rate |

25FPS |

||

| Focus mode |

Manual focus |

||

| Working temperature |

-10℃~+55℃ |

||

| Measurement and analysis | |||

| Temperature range |

-10℃~450℃ |

-10℃~550℃ |

-10℃~550℃ |

| Temperature measurement method |

Maximum temperature, minimum temperature and average temperature |

||

| Temperature measurement accuracy |

±2 or ±2% for -10℃~120℃, and ±3% for 120℃~550℃ |

||

| Measuring distance |

20mm~1m |

||

| Temperature correction |

Manual/Automatic |

||

| Emissivity correction |

Adjustable within 0.1-1.0 |

||

| Data sampling frequency |

It can be configured flexibly, such as 20FPS, 10FPS, 5FPS, 1FPS. |

||

| Image file |

Full-temperature JPG thermogram (Radiometric-JPG) |

||

| Video file |

MP4 |

||

| Device dimension | |||

| Single board |

220mm x 172mm, height of 241mm |

||

| Double board |

346mm x 220mm, height of 341mm |

||

| Data acquisition accessories (not included in standard configuration) | |||

| Heating table |

Standard configuration of 2 oiling test holes of resistance heating wires, which can be customized |

||

|

Customized adjustment of the simulated suction degree, duration and times of the suction pump |

|||

| Data acquisition |

Recording of temperature data without time limit, including temperature change data, data corresponding to resistance heating wires and resistance values, data corresponding to simulated power supply time and temperature, and calculation of heating uniformity |

||

Analysis mode

Circuit board analysis mode

Analysis mode of E-cigarette atomizer

Multi-dimensional analysis mode

Analysis mode of material thermal capacity

Defect analysis mode

Application Scenario

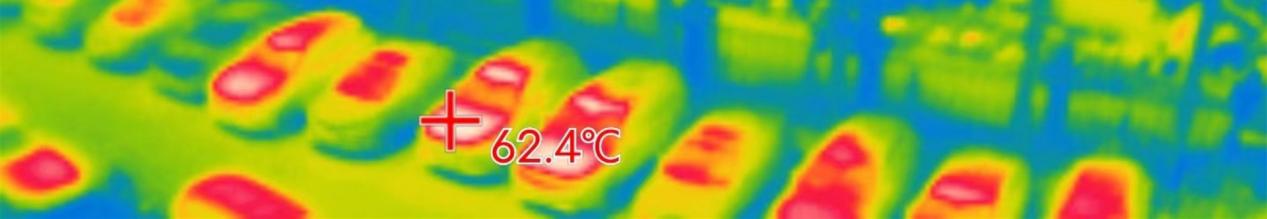

Detection and analysis of heat conduction material

When the heat conduction material conducts heat, different color blocks can be set to view the distribution of heat conduction.

Analysis of the thermal design of the circuit board

When the circuit board chip heats up, users can check the components affected by the heat to adjust the layout.

Temperature control analysis of E-cigarette

Quickly tracking the heating rate and temperature of the atomizer

Thermal quality analysis of products and components

The aging degree of the tested components can be analyzed through the simultaneous comparison of the standard samples and the tested samples.

Material heat dissipation analysis

The heat dissipation of different heat dissipation materials can be analyzed through the temperature color block.

Circuit board pulse heating analysis

The thermal analyzer can quickly capture the occasional pulse heat emitted by some components on the circuit board due to failure.

Heating capacity analysis of heating materials at different voltages and currents

The heating rate, heating efficiency and heating temperature of materials such as heating wire and heating sheet at different voltages and currents can be quantitatively analyzed.

Analysis of the corresponding relationship between voltage, current and temperature

Location detection of short circuit and leakage

When repairing the circuit board, the leakage position can be located through the first, second and third high temperature points.

Various accessories available

Fixed plate of atomizer test

Fixed atomizer resistance wire E-liquid injection test. Low resistance connector.

Automatic heating test bench for atomized electronic cigarettes

Automatic inhalation stimulation. Supporting the setting of pumping experiment times.

Experiment box

Simulating the temperature conditions of the equipment in a closed environment. Infrared thermal observation window with the diameter of 4cm. Built-in temperature sensor.

Power analyzer

Load voltage and current power analyzer, which can be connected to the analyzers from the specified manufacturers as required by customers.

Standard normal temperature reference

50℃ temperature reference for calibrating the accuracy of equipment temperature at normal temperature

Dianyang specially launched the CA pro series thermal camera analyzer, its optional in 200×260, 384×288 and 640×512 infrared resolution, equiped with our exclusive analysis software, can help you a lot in the works of PCB and hardware.

Our products and solutions delight in fantastic popularity among the our buyers. We welcome prospects, company associations and friends from all areas of the world to get in touch with us and seek out cooperation for mutual gains.

We have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to cooperate with you in the market.