Free sample for Thermal Camera Scanner - CA10 PCB Circuit board thermal analyzer – Dianyang

Free sample for Thermal Camera Scanner - CA10 PCB Circuit board thermal analyzer – Dianyang Detail:

copyright notice:The copyright of all contents of this manual belongs to shenzhen dianyang technology co., LTD. Without the permission of the company, Imitation, copy, quick copy or translation in any way is not allowed. No warranty, position or other implication of any kind is given in this manual.The product specifications and information mentioned in this manual are for reference only and will be updated without prior notice.

Product profile

Shenzhen DianYang Technology Co., Ltd. CA-10 PCB thermal analyzer, is a special equipment used for circuit board thermal field detection;In the era of rapid development of science and technology, intelligent devices is more and more popular, and intelligent device with low power consumption and lower heating is demanded higher and higher, so in the PCB product design and development stage, circuit board of the thermal design is very important, thermal analyzer at the design stage can provide heat thermal simulation experiment of a large amount of data, it is indispensable tool to the hardware design; At the same time, when the product failure, such as circuit leakage and short circuit board, abnormal temperature can be reflected , by using thermal analyzer, it can quickly find the leakage and short circuit device location and locate the fault point, so it can meet the purpose of rapid maintenance; In addition, it can test the effectiveness of some components, such as the power module and other devices, and the protection ability of overheating.

CA10 PCB circuit board thermal analyzer can be applied to:

l position detection and positioning service of PCB leakage, short circuit, open circuit ;

l mobile phones or other intelligent device comparative evaluation;

l effects of overheating protection components test;

l when circuit design, thermal simulation, fever rationality validation;

l product cooling capacity test;

device attachment

The thermal analyzer is connected to the computer through USB cable, no other lines are needed, and the connection is simple. After the connection is completed, open the switch of the thermal analyzer and directly open the analysis software on the computer, and it can work.

The computer operating system needs WIN10/WIN7 system, WIN10 system is recommended.

specification parameter

CA10 PCB Circuit board thermal analyzer:

| parameter | specification | |

| parameters | resolution | 260*200 |

| FPS | 25Hz | |

| NETD | 70mK@25℃ | |

| FOV | H 34.4,V 25.8 | |

| lens | 4mm Adjustable focus lens | |

| Measuring range | -10~170℃(can be extended to 550℃) | |

| Accuracy | ±2°C or ±2% | |

| interface | Power supply | USB 5V charge |

| Power switch | Press 1 second to turn on,3 second to turn off | |

| interface | USB connect to the PC | |

| PCB placement | Place floor | 2 pieces, can be disassembled and spliced |

| tripod | adjusting knob | 4 adjustment knobs, fast adjustment of up and down distance, fine adjustment of lens, front and back adjustment, lens tilt adjustment |

| physical parameter | Package dimension | Single floor:240mm x 163mmSplit double floor:326mm x 240mm height:353mm |

| Gross weight | ||

| Operationenvironment | Operating temperature | optimum working temperature 10℃~40℃ |

| operating humidity | <95% | |

| software | system requirement | Win10(recommention) win7 |

| PC requirement | I3 processor or above,More than 4G memory | |

| Update requirement | Connect to the Internet for manual or automatic updates | |

product features

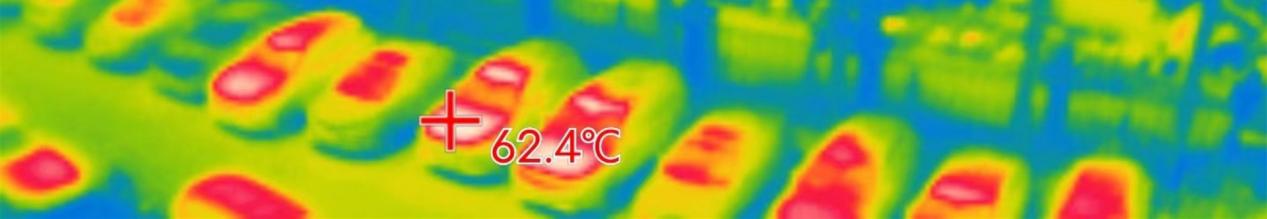

clear image

Can view the chip pin heat map changes, circuit board special color palette, can clearly display circuit board heat map changes

Elaborate structural design

Multiple adjustment knobs can quickly and stably adjust the lens

Multiple adjustment knobs, up, down, left, right, tilt, fine adjustment lens

20mm to 2000mm Double knobs can quickly adjust the distance and fine-tune the distance, which can adjust the front and back of the lens and the tilt of the lens. The focal length of the lens can be adjusted, and the working distance is from 20mm to 2000mm;

Removable and closed bottom plate

Single bottom plate can be used when the working table is narrow, and large area double bottom plate can be assembled when large circuit board needs to be detected。

Chute mounting bracket, bracket position can be moved at will

The side of the bottom plate adopts the installation chute, and the bracket can be moved freely in the bottom plate,

Standard 1/4 screw hole, removable for optional expansion

Standard 1/4 screw hole, removable bracket, can be adapted to different tripods, universal frame, extend the application range needs。

Rich application functions

The rich software functions are dedicated to the related applications of circuit boards:

l Can be used for circuit board short circuit, break, leakage fault maintenance;

l It can be used for heating experiment in circuit design;

l Power consumption design can be used in hardware circuit design;

l It can be used to evaluate and compare the heating condition of equipment;

l Heat dissipation design of products;

l Performance testing of thermal protection components;

Circuit board maintenance function

Text marking is available on the heat map,

It can check the key area and set the temperature width in the circuit board area separately

It can find the circuit board first, second, third……. High temperature point, find the real leakage position

The 3D mode can locate the minimal current leakage location

Double plate comparison

Double plate comparison:

l Used for mobile phone maintenance, normal plate and fault plate thermal field difference, to find the fault point

l It is used to detect temperature difference between normal device and fault device, and detect unqualified device: such as power module

l Used for product equipment evaluation, such as: mobile phone comparison evaluation

The difference can be compared through the regional temperature curve to detect the unqualified devices

The difference can be compared by the location of the highest temperature, lowest temperature and temperature values in the designated area

circuit design

Provide richer and more flexible functions for thermal field experiments and detection data collection in circuit design

Combined with thermal simulation software, it can check whether the circuit board design is consistent with the theory;

Isotherm, a temperature area can be marked as a color, convenient to improve the unreasonable place of the power circuit board design;

Provide more flexible temperature setting, can highlight the different temperature section of the circuit board, easy to find the first high temperature point, the second high temperature point, the third high temperature point of the circuit board……;

Provide more abundant temperature curve recording methods, suitable for different experimental applications

product packaging

CA-10 PCB The packing list of the circuit board thermal analyzer is as follows:

|

No. |

items |

quantity |

|

1 |

|

|

|

2 |

|

|

|

3 |

|

|

|

4 |

|

|

|

5 |

|

application case

Mobile phone circuit board maintenance, small home appliance circuit board maintenance, circuit board leakage location search, the location of leakage devices can be found through different temperature points

The location of The circuit board minimum current leakage can be found through 3D image, and along with the use of regulated power supply, the location of minimum current leakage can be found through the pulse change of leakage temperature.

Mobile phone evaluation: mobile phone fever level can judge the technology level of mobile phone products

Experimental data: in the circuit design, on the electrical state, data records, circuit board temperature changes can be set up alarm temperature, overtemperature occurs, the circuit make automatic video pictures, record the temperature curve

Note:

(1) The software is updated continuously, and the final interface of the software shall be subject to the user instruction manual;

(2) All thermal images of the analyzer are taken for practical application;

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for Free sample for Thermal Camera Scanner - CA10 PCB Circuit board thermal analyzer – Dianyang , The product will supply to all over the world, such as: Frankfurt, Lesotho, Muscat, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,